Why LED Display Heat Dissipation Technology is Critical?

Table of Contents

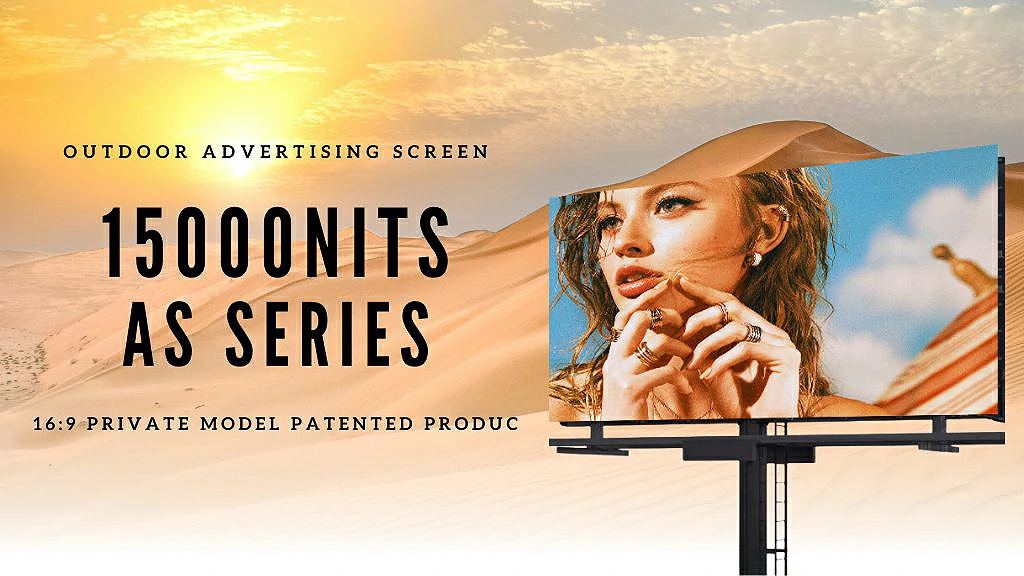

In the LED display industry, heat dissipation is often seen as the “invisible guardian of performance.” It not only affects display quality but also determines product lifespan, stability, and long-term ROI. As LED screens are widely used in high-load scenarios like outdoor advertising, command centers, live events, and cinemas, efficient thermal management has become a key standard for professional LED solutions.

1. Ensures Optical Performance Stability

LED chip efficiency is temperature-sensitive. Studies show that for every 10°C rise in junction temperature:

- Light output drops by 3%-5%

- Color temperature shifts over 200K

Advanced cooling systems (e.g., heat pipes + vapor chambers) can keep junction temps below 60°C, maintaining 95%+ brightness and delaying phosphor aging—critical for color accuracy in ads, cinemas, and high-brightness applications.

2. Boosts Cost Efficiency & Sustainability

- 35% of LED failures stem from overheating (burnt ICs, capacitor damage, etc.).

- Active cooling (e.g., liquid cooling) extends display lifespan from 5 to 8-10 years, slashing maintenance costs.

3. Enhances Durability in Extreme Conditions

For harsh environments (deserts, coastal areas, freezing climates), modular liquid cooling + smart thermal control keeps temperature fluctuations within ±5°C, with IP65/IP66 protection for reliable operation at -40°C to 85°C.

The Bottom Line:

As LED displays evolve toward higher brightness and resolution, heat dissipation is no longer optional—it’s a competitive edge for performance, safety, and ROI.

👉 Need a high-performance LED display with advanced thermal management? Contact us for tailored solutions!