High Power LED Packaging: Boosting Efficiency & Reliability

Table of Contents

In the field of high-end lighting, LED display and outdoor advertising, high power LED packaging technology is becoming the core driving force to improve performance. As the market demand for high brightness, long life and high stability continues to grow, encapsulation materials and processes continue to evolve, helping the LED industry to move to a higher level of development.

1.The core value of LED package

LED package not only protects the chip, but also determines the light efficiency, heat dissipation and overall life. Its main roles include:

- Efficient Heat Dissipation: Through ceramic substrate, heat pipe and other technologies, it effectively reduces the junction temperature of the chip and prolongs the service life of the product.

- Light efficiency enhancement: Using high refractive index silicone and precision optical design to maximize light output efficiency and reduce energy loss.

- Enhanced protection: Improve impact resistance, dustproof and waterproof performance to ensure stable operation of LEDs in harsh outdoor environments.

- Current stabilization: integrated high-efficiency driver circuit, precise control of current output, preventing light degradation phenomenon.

2.Key technological breakthroughs in high-power LED packaging

2.1Low thermal resistance packaging

- Adopting aluminum nitride substrate and silver sintering process, the thermal resistance is reduced to 0.5℃/W, which significantly reduces heat accumulation and effectively extends the service life of LEDs.

2.2 High light extraction rate package

- Through the refractive index gradient technology and anti-reflective coating design, the light extraction efficiency is increased by more than 30%, making the LED display brighter and energy-saving.

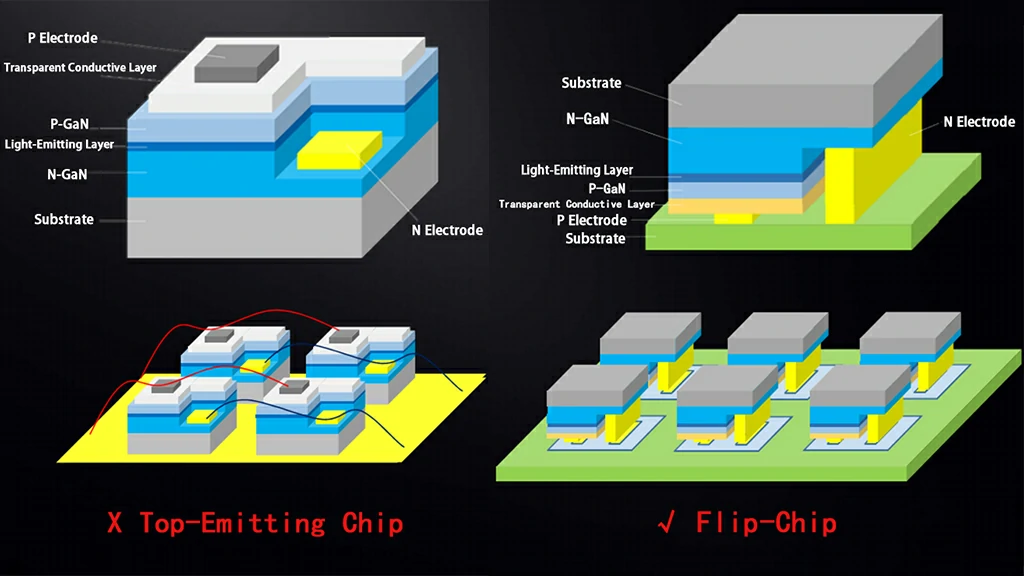

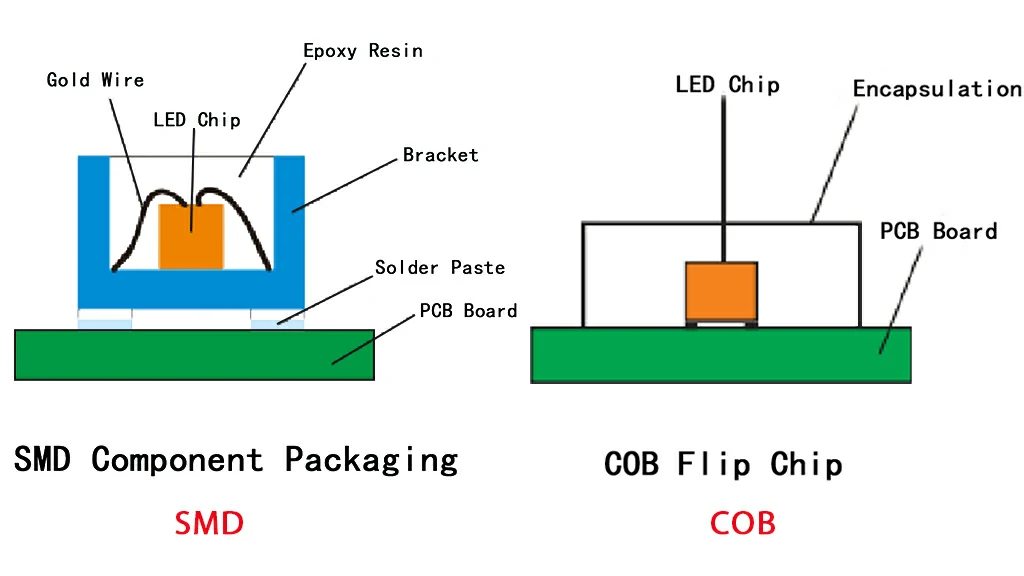

2.3 Comparison of SMD and COB package technology

- SMD package: mature and reliable, suitable for outdoor LED display applications, supports ultra-small pixel pitch as small as P0.7, high brightness and good consistency.

- COB package: the chip is directly encapsulated on the substrate, better heat dissipation, especially suitable for ultra-small pitch and high-end display scenes.

2.4 Material innovation empowers

- Adopting aluminum nitride substrate and silver sintering process, the thermal resistance is reduced to 0.5℃/W, which significantly reduces heat accumulation and effectively extends the service life of LEDs.

3.Future Packaging Trends

- Wafer-Level Packaging (WLP): Adapted to Micro LED applications, improving system integration and light efficiency.

- Self-healing materials: Extend the package life and cope with the potential failure risk caused by micro-cracks.

- Intelligent temperature control technology: integrated sensors monitor and adjust the heat dissipation system in real time to optimize the overall performance.

4.Conclusion

The continuous breakthrough of high-power LED packaging technology not only improves the performance of LED display and high-end lighting products, but also broadens the application boundary. In the future, with the landing of new materials, new technology and intelligent packaging solutions, LED products will realize higher luminous efficacy and stronger reliability in outdoor advertising, vehicle display, industrial lighting and other fields, and meet broader development opportunities.